Ntaub Ntawv Qhia Txog Kev Txawj Ntse

|

Soj Ntsuam Cov Khoom |

CMM, Projector, Calipers, Micro caliper, Xov Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter thiab lwm yam. |

|

Qhov Raug Yog |

* Qhov tseeb ntawm Machining: +/- 0.005mm * Qhov tseeb ntawm Kev Sib Tsoo: +/- 0.005mm * Nto Roughness: Ra0.4 * Parallelism: 0.01mm * Ntsig: 0.01mm * Kev Sib Tsoo: 0.01mm |

|

Daim ntawv pov thawj |

SGS / Cov ntaub ntawv pov thawj / Cov Ntawv Tshaj Qhia Kev Ntsuas |

|

Daim Duab Qauv |

2D Kos duab: PDF, DWG / DXF thiab lwm yam. Daim duab 3D: IGS, STEP, STP thiab lwm yam. |

|

Txoj kab uas hla |

0.1-25 hli |

|

Ntev |

kev npam |

|

Ntxawg |

Ra0.4-Ra0.8 |

| Cov khoom siv | CuZn25Al5Mn4Fe3 / CuSn8P |

| Daim Ntawv Thov raug | Tshuab-cuab tam, Agricultural tshuab, Crane electromotor, Caij nplooj ntoos hlav pin, Kauj ruaj ruaj thiab kis, thiab lwm yam |

| Qhov ceev g / cm3 | 8.7 |

| Max Dynamic Load N / mm2 | 60 |

| Max Tawm Txiag Tsis Txaus (Roj) m / s | 0.85 |

| Max PV tus nqi Roj N / mm2 · m / s | 1.65 |

| Lub zog muaj zog N / mm2 | > 240 |

| Tawm Tawm Zog N / mm2 | > 100 |

| Mating Axis | Hardness ≥40, Nyuaj 0.4 ~ 1.0 |

| Ua Haujlwm Kub ℃ | 40 ~ 140 |

| Txhuam Txhuam Coefficient | 0.09 ~ 0.15 |

| coefficient ntawm tshav kub ua tiav W / m · K | 52 |

| Cag qaum kev nthuav dav coefficien | 18.5 × 10-6 / K |

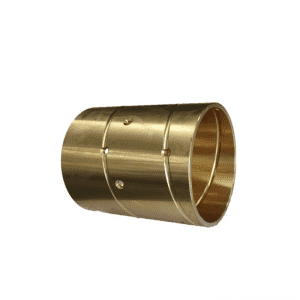

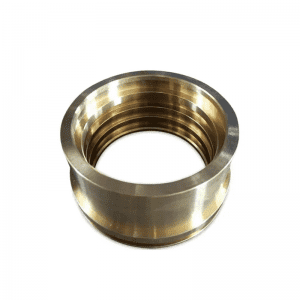

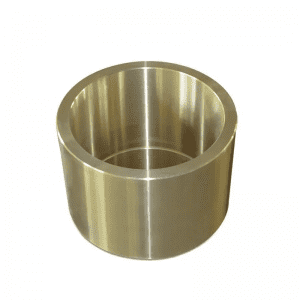

| Khoom Npe | Mekas Brass Bushing Hlau Bushings Rau tshuab qhov chaw |

| Cov khoom siv | Stainless hlau: 303, 304, 316, 412,201,202 thiab lwm yam Hlau: Carbon steel / tuag steel, CRS thiab lwm yam Aluminium alloy: 6061, 6063, 5052, 2017, 7075, thiab lwm yam Brass alloy: 3602, 2604, H59, H62, tooj liab, phosphor tooj dag, thiab lwm yam Yas: Nylon, PP, POM, thiab lwm yam Lwm cov ntaub ntawv muaj nyob |

| KEV KHO MOB | Anodizing, Polishing, Hmoov txheej, Passivation, Sandblasting, Nickal plating, Zinc plating, Chrome plating, Kev kho cua sov, Oxidation |

| Ua Kev Tsim Qauv | CNCTurning, CNC Milling, CNC Tshuab Dhos thiab lwm yam. |

| EQUIPMETS | CNC tshuab xuas nrig ntaus, CNC milling tshuab, CNC xa tshuab, CNC machining chaw, Tsis siv neeg lathes, Kab txiav, Sib tsoo tshuab thiab lwm yam. |

| DAIM NTAWV THOV | Hluav taws xob, pib, siv tshuab hluav taws xob, tshuab hluav taws xob, khoom ua si, kho mob, kho hluav taws xob luam yeeb hauv tshuab muaj hlau, lub suab nrov lub thawv, rooj tog thiab cov khoom siv dag zog thiab lwm yam lag luam. |

| MAIV NYIAJ LAG | Tebchaws Asmeskas, UK, Spain, Lub Tebchaws Yelemees, Ltalis, Switzerland, thiab lwm yam |

| HOOBKAS LOS SIS LUAG HAIS | Peb yog lub chaw tsim khoom. |

Kho deg

| Aluminium qhov chaw | Stainless hlau qhov chaw | Qhov hlau | Nrig tooj daj |

| Liam Anodized | Polishing | Zinc Plating | Npib Tsib Xee Plating |

| Xim Anodized | Xav Hla Tebchaws | Oxide dub | chrome plating |

| Sandblast Anodized | Khawv Koob | Npib Tsib Xee Plating | Electrophoresis dub |

| Tshuaj Zaj Duab Xis | Laser engraving | Chrome Plating | Oxide dub |

| Kev txhuam | Electrophoresis dub | Raug txim | Hmoov txheej |

| Polishing | Oxide dub | Kev kho cua sov | |

| Sijhawm | Hmoov Coated | ||

| Kev Kho Cua Sov | Tempering | Kev Nyuaj Siab |

Cov:

| Thawv Loj | 29 * 20 * 13 CM lossis tus neeg yuav khoom thov |

| Pallet loj | 120 * 80 * 80 CM lossis tus neeg thov |

| Lub sijhawm ua | 3-7 hnub ua haujlwm li niaj zaus.Nws yuav raws li cov ncauj lus kom ntxaws khoom ntau. |

|

Cov Lus Qhia |

Txoj Kev 1: Txo zaj duab xis, tom qab ntawd thau cov khoom loj |

| Txoj Kev 2: Txheem zaj duab xis + lub thawv + pallet / ntoo rooj plaub | |

| Txoj Kev 3: PP + ntoo rooj plaub | |

| Txoj Kev 4: Raws li ib tus neeg siv cov kev xav tau lossis kev sib tham |